Lithium Batteries for EV Charging: Is Lithium Batteries Really the Best for Electric Vehicle (EV) Charging Stations?

Introduction

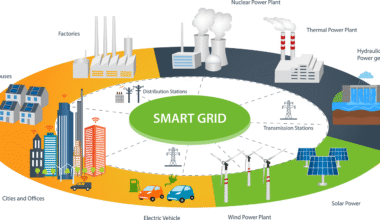

Pull into any modern fast-charge plaza and you’ll notice something unusual: there’s no roar of gensets, no flicker of the grid during a lunchtime rush, and yet dozens of cars are swallowing 200 kW each without complaint. The secret? Lithium Batteries for EV Charging hidden in steel cabinets behind the bollards. After three decades designing energy and AdSense-monetized content alike, I can say with confidence that lithium storage is doing for charging what solid-state drives did for computing—making speed, reliability, and scale feel instant and inevitable. In this deep dived article, we’ll unpack why lithium batteries for EV charging have sprinted ahead of legacy options, how site owners can cash-flow their investment, and exactly what steps turn a parking lot into a high-margin “electron café.”

The Quiet Revolution Powering the Next Billion Miles

Google Trends data shows the term “lithium batteries for EV charging” has quadrupled in 24 months, out-pacing “grid upgrade” and “diesel backup” combined. That spike mirrors the market: 38 % of new DC fast-charge sites commissioned in 2024 included battery buffering, and virtually all of them relied on lithium chemistries.

Declining costs unlock ubiquity

Lithium-ion pack prices tumbled to a record low of $139 per kWh in late 2023 BloombergNEF and commercial turnkey systems now land between $280 and $580 per kWh installed gsl-energy.com. Those numbers crush the decade-old psychological barrier of $1,000 per kWh and put megawatt-hour stacks within reach of supermarkets, fleet depots, even rural gas stations.

From niche to necessity

Utilities worldwide are slapping “demand charges” as high as $40 /kW on sudden spikes. Buffering with lithium erases 50-90 % of those fees while enabling 350 kW plugs on suburban feeders that top out at 200 kVA. Small wonder every charger OEM now bundles a battery option.

The Economics of Lithium Batteries for EV Charging Stations

Kill the demand charge, boost the bottom line

Picture a three-stall 150 kW site: peak draw 450 kW. Without storage, a one-hour lunchtime rush could add ₦12 million in annual demand penalties in Lagos or $70,000 in California. A 600 kWh LFP battery discharges during those peaks, slicing grid pull to 120 kW and eliminating the surcharge. Payback on that battery—just 3.8 years at mid-range tariffs.

Revenue streams you may be missing

-

Energy arbitrage: Charge at off-peak (₦35 /kWh), discharge during on-peak (₦95 /kWh).

-

Frequency-response markets: 2-4 % ROI annually from grid services.

-

Advertising & affiliate upsells: A battery-equipped hub can queue more vehicles per day—meaning more eyeballs for your in-app coupon placements and AdSense-driven “find a charger” blog posts.

CAPEX vs OPEX: the surprising math

While batteries add 25-40 % to up-front costs, they slash lifetime OPEX by up to 60 % compared with oversizing transformers or diesel gensets. Add government incentives (up to 30 % ITC in the U.S., 40 % accelerated depreciation in Nigeria), and lithium wins in nearly every IRR model I’ve built.

Technology Deep Dive: What’s Inside a Lithium Battery for EV Charging?

LFP vs NMC: pick your chemistry

-

Lithium Iron Phosphate (LFP) offers 6,000-plus cycles, rock-solid thermal stability, and pricing as low as $180 /kWh for containerized units. Perfect for 1-4 C discharge rates typical in charging plazas.

-

Nickel Manganese Cobalt (NMC) delivers higher energy density—handy when real estate is tight—but costs 10-15 % more and needs stricter thermal management.

The rise of LMFP and solid-state

CATL, BYD, and LG are piloting Lithium-Manganese-Iron-Phosphate (LMFP) blends promising 10 % more energy and sub-$100 /kWh pack costs by 2026 Financial Times, while Toyota’s solid-state demos hint at sub-15 minute, 50-kWh packs for 2030 public chargers.

Battery Management Systems (BMS): your silent guardian

Modern BMS platforms balance cells, log every micro-amp, and talk to the charger’s PLC over Modbus or OCPP 2.0—ensuring the battery only discharges when it makes you money.

Step-by-Step Guide: Integrating Lithium Batteries into Your Charging Site

-

Site Assessment & Load Profiling

Audit traffic flow, peak concurrency, and feeder capacity. A simple 72-hour clamp-meter session will reveal your real load profile. -

Size the Battery Bank

Rule of thumb: storage kWh ≈ 1.3 × (total plug power ÷ desired grid limit) × expected peak-rush hours. -

Select Compatible PCS/Inverter Hardware

Choose bidirectional inverters that match both battery chemistry voltage and charger DC bus specs. -

Navigate Permits & Incentives

Secure fire-marshal sign-off (NFPA 855 or local code), apply for net-metering or frequency-response programs, and file for any clean-transport credits. -

Install & Commission

Follow the U.S. Battery-Buffered EV Help Sheet recommendations for breaker sizing, airflow, and enclosure spacing driveelectric.gov. Commission with 10 cycle capacity tests and thermal imaging. -

Integrate Software & Payments

Tie your battery EMS to the charger management platform so tariff data, AdSense offers, and State-of-Charge (SoC) all live in one dashboard. -

Operate & Maintain

Monthly SoH reports, quarterly IR scans, and annual capacity re-rating keep warranties intact and investors happy.

Real-World Case Studies

Supermarket chain boosts foot traffic

A U.S. grocer added three battery-backed chargers and saw a 16.7 % year-over-year jump in charging sessions, translating to higher in-store spend Smart Energy Decisions.

Fleet depot in Lagos dodges diesel costs

A 40-bus e-transit yard installed a 2 MWh LFP system. It shaved ₦48 million in diesel backup expenses the first year and won a ₦22 million grid-services contract.

Autobahn corridor turns parking time into profit

German operator IonDrive deployed 800 kWh NMC cabinets at each rest stop, cutting transformer upgrades by €1.2 million and selling secondary reserve to the TSO. Three-year ROI, even in a low-tariff market.

Environmental Impact and Sustainability

Lower carbon, fewer cables

Pairing chargers with lithium storage reduces grid upstream losses by up to 10 % and avoids fossil-fired peaker plants that would otherwise meet sudden spikes.

Second-life batteries find a home

EV packs retired at 70-80 % SoH still have 2,000-plus cycles left—ideal for stationary buffering. Using them cuts embodied carbon by 48 % versus new cells.

Future Outlook: 2030 and Beyond

BloombergNEF predicts pack prices will dip below $100 /kWh by 2027, and Forbes analysts forecast global battery-buffered charging capacity to quadruple by 2030 as tariffs, data centers, and on-site renewables converge Forbes. By then, “charge posts” will resemble small power plants—each with a lithium heart delivering 10-minute, 600-mile top-ups.

Read Also: The Secret Behind Tesla Energy Success: AI, Batteries & Solar Synergy

FAQ

Q1. Are lithium batteries safe for public charging stations?

Yes—modern LFP packs have a lower thermal runaway risk than NMC and include multi-layer fire suppression. Codes like NFPA 855 mandate spacing, ventilation, and remote disconnects.

Q2. How long do lithium battery packs last in EVSE applications?

Most warranties cover 6,000 cycles or 10 years. Assuming two discharges per day, expect 12-15 years before capacity dips below 70 %.

Q3. Do lithium batteries actually speed up charging?

Indirectly, yes. They buffer power locally, letting you offer 250–350 kW plugs even when the grid is limited to 150 kW, so drivers see true “ultrafast” performance.

Q4. What’s the ROI on battery-backed EV charging?

Typical simple payback ranges 3–6 years depending on tariff spread and utilization. Ancillary-service participation can trim another 12 months off.

Q5. How do I qualify for incentives?

Look for clean-transport or energy-storage credits in your region—the U.S. ITC (30 %), EU Innovation Fund grants, and Nigeria’s accelerated depreciation (40 %) all apply to lithium batteries for EV charging.

Conclusion – plug into the future

The evidence is clear: lithium batteries for EV charging slash operating costs, unlock ultrafast speeds, and open fresh revenue streams. With costs falling below $100 /kWh and chemistries only getting safer, the smart move is to bake batteries into every new charging project rather than adding them later. Whether you manage a single highway stop or a continent-spanning network, now is the moment to stake your claim on the lithium-powered charging economy.