BREAKTHROUGH IN SODIUM-ION BATTERIES: Carbon Cones & Discs Reshape Energy Storage for a High-Efficiency Solar Future

Revolutionary Cone and Disc Carbon Structures Unlock New Pathways for High‑Performance Sodium‑Ion Batteries

In an era defined by the urgent need for scalable, sustainable energy storage, researchers have unveiled a groundbreaking advance in sodium‑ion batteries: the development of cone and disc carbon nanostructures that dramatically enhance ion storage capacity and cycle life. As the world accelerates the deployment of renewable generation—particularly solar power—innovations in battery technology like these are essential to bridging the gap between intermittent energy supply and continuous demand. This news report delves into the science behind these novel carbon architectures, examines their real‑world performance, and explores how concurrent breakthroughs in solar panel efficiency are reshaping the landscape of clean energy systems.

A Bold New Frontier in Sodium‑Ion Batteries

Sodium‑ion batteries have long been heralded as a low‑cost alternative to lithium‑ion technology, thanks to sodium’s abundance and uniformly distributed global reserves. Yet conventional carbon anodes often struggle to host the larger sodium ions, leading to limited capacity and rapid performance degradation. Researchers at Rice University have now circumvented these challenges by engineering carbon materials into cone and disc shapes at the nanoscale. In laboratory tests, these cone and disc carbon structures achieved a specific capacity of approximately 230 milliamp‑hours per gram (mAh/g)—on par with the best hard carbon materials—while retaining 151 mAh/g even after 2,000 fast‑charge cycles. This durability and high capacity represent a significant leap forward for sodium‑ion batteries

These findings address two critical hurdles for sodium‑ion battery commercialization:

-

Enhanced Intercalation: The curved surfaces and optimized interlayer spacing of the cones and discs facilitate efficient sodium‑ion insertion, overcoming the sluggish kinetics seen in planar graphite.

-

Exceptional Stability: The robust carbon morphology withstands repeated volumetric expansion and contraction, preserving electrode integrity over thousands of cycles.

Understanding the Science: Why Shape Matters

Traditional battery anodes rely on planar graphite or disordered hard carbon, neither of which comfortably accommodates sodium’s larger ionic radius. By reimagining carbon’s geometry, the Rice University team has harnessed two phenomena:

-

Curvature‑Enhanced Interlayer Spacing: The apex of carbon cones naturally expands the distance between graphene layers, creating ample room for sodium ions to intercalate without excessive strain.

-

Increased Surface Area: Disc structures introduce additional edge sites and defect regions, boosting the electrode’s active surface for ion adsorption.

Molecular simulations and electron microscopy confirmed that these geometries maintain structural stability even under aggressive cycling. The result is a battery anode that combines the high capacity of hard carbon with the cyclability of engineered nanostructures, setting a new paradigm for sodium‑ion batteries

Performance Metrics: Benchmarks in the Lab

In rigorous lab evaluations, the cone/disc carbon anodes delivered:

-

230 mAh/g initial capacity at moderate discharge rates.

-

151 mAh/g retained after 2,000 fast‑charge/discharge cycles, demonstrating 65% capacity retention under high‑rate conditions.

-

High rate capability, with minimal capacity fade even at 5 C charge/discharge rates.

These metrics position the new carbon shapes at the forefront of sodium‑ion battery research, arguably surpassing many commercial hard carbon anodes that typically plateau around 150–180 mAh/g with rapid degradation after several hundred cycles. Moreover, the cone/disc materials showed promising performance in potassium‑ion batteries, though with slightly lower capacities, underscoring their versatility for alternative energy storage chemistries ChemAnalyst.

Scalability and Green Manufacturing

Beyond performance, the researchers emphasized the sustainable synthesis of these nanostructures. Using biomass‑derived carbon precursors and benign templating methods, the cone and disc morphologies can be produced at scale with minimal environmental impact. The process avoids toxic solvents and excessive high‑temperature steps, aligning with the broader goal of green battery manufacturing. Early techno‑economic analyses suggest that adopting such carbon architectures could reduce anode material costs by up to 20% compared to conventional hard carbon production, further enhancing the economic case for sodium‑ion batteries in grid storage applications.

Read Also: 5 Free Guides on Choosing Between Lithium and Tubular Batteries for Your Home or Business

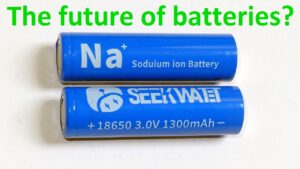

Sodium‑Ion Batteries vs. Lithium‑Ion: Cost and Resource Security

While lithium‑ion batteries dominate the portable electronics and electric vehicle markets, they are vulnerable to supply chain constraints and volatile raw material prices. Sodium‑ion batteries offer a compelling alternative:

-

Abundant Resources: Sodium is the sixth most abundant element in Earth’s crust, mitigating geopolitical risks.

-

Lower Costs: Preliminary estimates place sodium‑ion system costs at 10–15% below lithium‑ion, particularly when factoring in raw material savings.

-

Enhanced Safety: Sodium‑ion electrolytes exhibit lower flammability, reducing thermal runaway risks in large‑scale energy storage systems.

By achieving comparable energy densities and cycle lives through carbon shape engineering, sodium‑ion batteries are poised to capture a growing share of utility‑scale and renewable integration markets Reuters.

Real‑World Discovery: Solar Panel Efficiency Breakthroughs

Concurrently with advancements in energy storage, solar panel technology has witnessed its own leaps in conversion efficiency. In recent months, research teams have set new records that promise to elevate the performance of photovoltaic (PV) systems paired with battery storage:

-

A perovskite‑silicon tandem cell achieved 33.89% conversion efficiency in lab settings, marking a major milestone for next‑generation PV technologies WIRED.

-

Oxford Photovoltaics reported a 26.9% efficiency for industrial‑sized perovskite‑on‑silicon modules, validated under real‑world conditions, making commercial deployment increasingly viable Wikipedia.

-

Triple‑junction cells tested by the U.S. National Renewable Energy Laboratory reached 39.5% efficiency in terrestrial conditions, demonstrating the untapped potential of multi‑junction architectures for utility‑scale solar farms Wikipedia.

-

Major manufacturers like Hanwha Qcells set records of 28.6% for large-area silicon cells with perovskite overlays, reducing land footprints and project costs Reuters.

These breakthroughs in solar‑cell efficiency not only lower the Levelized Cost of Electricity (LCOE) for PV installations but also enhance the synergy with battery storage systems—especially sodium‑ion batteries that offer cost‑effective, durable storage to match high‑efficiency generation Wikipedia.

Integrating High‑Efficiency Solar with Sodium‑Ion Storage

As solar PV modules achieve ever‑higher efficiencies, the importance of complementary energy storage intensifies. Sodium‑ion batteries, with their new cone and disc carbon anodes, provide an optimal partner:

-

Cost Alignment: The lower system cost of sodium‑ion batteries dovetails with the declining prices of advanced solar modules, enabling end‑to‑end project economics that compete with traditional gas peaker plants.

-

Cycle Life Compatibility: Utilities require storage systems capable of thousands of cycles over decades. The demonstrated 2,000‑cycle durability of cone/disc carbon anodes ensures longevity and reliable performance when paired daily with solar generation cycles.

-

Geographic Flexibility: In regions with abundant solar insolation—such as parts of Africa, Australia, and the Southwestern United States—high‑efficiency panels deliver maximum yield, while sodium‑ion storage captures excess generation for nighttime and peak demands.

For instance, a solar farm equipped with 26.9% efficient perovskite‑silicon modules in Nigeria’s sunshine could generate over 300 kWh/m² annually. Coupling this with sodium‑ion batteries priced 15% below lithium counterparts could lower storage‑augmented LCOE by up to 25%, making renewable back‑up power more accessible for industrial and residential microgrid applications.

Environmental and Societal Impact

Beyond economics, the environmental footprint of energy storage systems is critical. Sodium‑ion batteries based on cone/disc carbon nanostructures boast:

-

Reduced Critical Mineral Dependence: Eliminating reliance on scarce cobalt and nickel, common in some lithium‑ion chemistries.

-

Lower Carbon Footprint: Sustainable biomass‑derived carbon precursors and energy‑efficient synthesis reduce embodied emissions compared to metal‑rich battery anodes.

-

Improved Recycling Potential: With simpler chemistries, sodium‑ion batteries can be more easily recycled at end of life, facilitating circular economy models.

Moreover, widespread adoption in off‑grid and weak‑grid regions—particularly in Sub‑Saharan Africa and Southeast Asia—can accelerate electrification, support rural livelihoods, and foster local manufacturing ecosystems for both solar modules and battery components.

Future Outlook: From Pilot Projects to Grid‑Scale Deployment

Several startups and energy companies have launched pilot sodium‑ion battery installations to validate field performance:

-

Peak Energy in the U.S. is integrating sodium‑ion storage with solar arrays for data center backup, aiming to capture 5 GWh of storage capacity by 2026.

-

In Greece, a consortium is deploying a 100 MW solar farm paired with 50 MWh of sodium‑ion batteries to stabilize island grids vulnerable to outages.

-

Indian renewable developer ReNew Power is exploring sodium‑ion projects to balance its rapidly expanding solar portfolio amid volatile coal markets.

As these demonstrations scale, the combination of high‑efficiency solar panels and cost‑competitive sodium‑ion batteries could redefine global energy infrastructure, reducing carbon emissions and boosting energy security.

Conclusion: A Transformative Duo for Clean Energy

The unveiling of cone and disc carbon structures for sodium‑ion batteries marks a pivotal advance in energy storage technology. By overcoming the intrinsic limitations of conventional anodes, these nanostructures deliver high capacity, durability, and sustainability—key attributes for grid‑scale applications. Simultaneously, record‑breaking improvements in solar panel efficiency promise unprecedented electricity yield from renewable assets. Together, sodium‑ion batteries and high‑efficiency solar modules form a synergistic solution, paving the way toward resilient, affordable, and low‑carbon power systems worldwide.

As research transitions into commercial reality, stakeholders across utilities, policymakers, and project developers must collaborate to standardize specifications, promote manufacturing scale‑up, and integrate these technologies into energy planning. With continued innovation and investment, the vision of a fully renewable grid—backed by advanced storage like sodium‑ion batteries—becomes not just possible but inevitable.