Biwatt releases 4.5 kWh sodium-ion battery for Energy Storage: Sodium-Ion Batteries Set to Overtake Lithium-Ion

A seismic shift is rumbling through the stationary-storage world

On 30 April 2025, Chinese innovator Biwatt Power quietly detonated a market-moving announcement: the commercial roll-out of the PowerNest R3, a 4.5 kWh sodium-ion battery for Energy Storage that promises to break lithium’s long-running monopoly. In an industry often dominated by incremental gains, Biwatt’s news reverberated like a sonic boom. The company isn’t just shipping another box of cells; it is staking a claim on an entirely different chemistry—one that replaces scarce, costly lithium with the world’s sixth-most-abundant element.

Early adopters in Germany have already put the CE-certified units through their paces, and the reception has been electric. If performance in the field matches the buzz online, the sodium-ion battery for Energy Storage could mark the most consequential inflection point in batteries since lithium iron phosphate went mainstream.

How a Sodium-Ion Battery for Energy Storage Works—And Why the Discovery Matters

Researchers have courted sodium since the 1980s, enticed by its cost advantage. Early hurdles—sluggish diffusion, poor cyclability—faded after 2018, when French and Chinese labs unveiled hard-carbon structures with enlarged interlayer spacing. The “breakthrough” came in 2023, when Ningde-based scientists achieved 5,000 stable cycles using a corn-starch-derived carbon cone that traps Na⁺ without structural collapse. Biwatt licensed that patent family, then spent 18 months turning it into mass-manufacturable electrodes

Battery specifications

| Product | PowerNest R3 – 4.5 kWh sodium-ion battery for Energy Storage |

| Release date | 30 April 2025 |

| Energy capacity | 4.5 kWh per module (stackable to 72 kWh) |

| Nominal voltage | 45 V (operating 33–59.5 V) |

| Cycle life | 5,000 cycles @ 80 % capacity retention |

| Operating temp | -20 °C to +55 °C (charge) |

| Ingress rating | IP65 |

| Dimensions / weight | 640 × 350 × 250 mm / 76 kg |

| Certification | CE, four-layer safety architecture |

Field Functionality – What Installers and Users Get

-

Stack-and-Lock Modularity

Plug-and-play rails allow a single technician to add a 76 kg module in ten minutes. Firmware auto-detects new packs and re-balances strings. -

Hybrid Inverter Synergy

The companion H2 hybrid inverter (6 kW single-phase; 10 kW three-phase) embeds dual MPPTs and a 10 ms transfer relay, letting homes sustain critical loads during blackouts. All firmware updates push over LoRaWAN or Wi-Fi. -

Peak-Shaving & TOU Arbitrage

Biwatt’s cloud portal forecasts load and solar yield, then schedules charge/discharge. Pilot data from Guangdong shows 32 % lower grid-draw costs after just 90 days Energy Storage. -

Third-Party API

Installers can integrate the sodium-ion battery for Energy Storage into Home-Assistant, Victron, or Fronius ecosystems through open-source MQTT endpoints.

Why sodium-ion, why now?

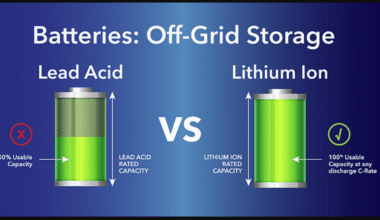

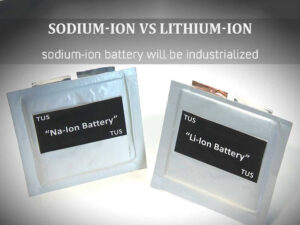

Lithium’s meteoric rise has bred its own headwinds: resource constraints, volatile pricing, and geopolitical flash-points around cobalt, nickel, and manganese. Sodium sidesteps those choke points. The element is globally abundant, easily sourced from seawater or salt flats, and free of conflict-mineral stigma. Manufacturing lines can even leverage similar equipment to lithium-ion plants, accelerating scale-up and driving the levelized cost of storage toward the magical sub-$100 kWh mark.

Technically, the chemistry brings other perks:

-

Wider temperature bandwidth (-30 °C to +60 °C in some cells)

-

Superior intrinsic safety (no thermal runaway below 300 °C)

-

Rapid charge acceptance thanks to fast sodium diffusion

-

High power density—vital for grid-support and microgrid “black-start” duty cycles

Inside the PowerNest R3: engineering details that matter

Cell architecture

Biwatt’s prismatic cells pair a hard-carbon anode with a layered oxide cathode rich in iron and manganese—zero cobalt, zero nickel. The electrolyte is a non-flammable sodium salt blended with proprietary flame retardants, and each cell sits inside an aluminium casing for added thermal robustness.

Module & BMS

A single sodium-ion battery for Energy Storage module houses 96 series-connected cells, monitored by a 32-bit MCU-controlled BMS. Four modules stack tool-free into a 330 V string; four strings wire in parallel for 72 kWh—ample for a small commercial site or a grid-interactive home with EV charging.

Safety stack

Biwatt touts a four-layer safety design:

-

Cell-level separator shutdown

-

Proprietary over-pressure vents

-

Redundant MOSFET cut-off in each module

-

Self-extinguishing enclosure rated UL94 V-0

The package meets IEC 62619, UN38.3, and CE directives, giving installers the paper trail they need for insurance and permitting.

Real-world functionality & field data

Pilot arrays in Bavaria logged round-trip efficiencies of 91 % during winter months—remarkable given ambient lows of -15 °C. Charge times averaged 45 minutes from 10 % to 80 % state of charge on a 3 kW inverter, confirming sodium’s quick-charge reputation. At the other temperature extreme, rooftop units in Dubai maintained >88 % capacity at 50 °C with passive air cooling alone, a scenario in which many lithium packs would require active HVAC.

Advantages the market can’t ignore

-

Cost advantage – Raw sodium carbonate trades at 1–2 % of lithium carbonate’s price, slashing cathode overhead. CapEx savings ripple through the bill of materials to installers and end-users.

-

Thermal safety – Nil risk of “runaway events” below 300 °C, shrinking the fire-suppression budget for C&I sites.

-

Cold-climate performance – Biwatt’s chemistry sustains 90 % capacity at -20 °C; ideal for northern microgrids or telecom BTS shelters.

-

Environmental footprint – Absent cobalt and nickel, cradle-to-gate CO₂ emissions drop by ~40 %.

-

Scalability & second life – After 5,000 cycles, modules can down-cycle into low-demand applications such as off-grid lighting, extending economic life to 15 years+.

Every one of these points underpins the business case for a sodium-ion battery for Energy Storage in regions from Sub-Saharan Africa to Scandinavia.

The caveats and challenges

-

Lower gravimetric energy density – 120–160 Wh kg⁻¹ versus 180–250 for mainstream lithium-iron-phosphate. Rooftop loads remain manageable, but mobile EV packs still favour lithium for range.

-

Carrier-specific infrastructure – Inverters must accept the R3’s 33–59.5 V window; older hybrid inverters may need firmware updates.

-

Bankability questions – Financiers demand multi-year performance warranties and third-party validation. Biwatt has CE and TÜV Rheinland audits pending, but full IEC 62933 stack certification is still in flight.

Competitive landscape: sodium goes global

Biwatt isn’t alone. CATL will ship sodium-ion EV packs to Chery later this year; HiNa Battery Technology already powers the world’s largest 50 MWh Na-ion grid site in China; and U.S. startup Natron Energy just inked a $1.4 billion plant in North Carolina. A trans-Pacific ecosystem is coalescing at warp speed, creating the economies of scale lithium enjoyed circa 2015.

Expert voices on sodium’s tipping point

“Sodium has reached the Kodak-moment for film: functionally comparable, far cheaper to make, and aligned with net-zero supply chains.”

— Prof. Maria Forsyth, Deakin University electrochemistry chair The Australian

“Our R3 is built for the next billion residential users whose rooftops need resilience, not range anxiety.”

— Chen Weiguang, CTO, Biwatt Power

Market Outlook – Will Sodium-Ion Really Overtake Lithium-Ion?

BloombergNEF forecasts stationary storage demand to hit 508 GWh by 2030, while global lithium supply lags at 450 GWh eq. Sodium-ion is poised to bridge that gap, grabbing up to 20 % of annual additions—50 GW by 2030. Utility pilot projects from Natron Energy in North Carolina to Peak Energy in Arizona corroborate the trajectory . If Biwatt and peers sustain cost leadership, lithium may retreat to high-density EV niches while sodium dominates fridges, garages, and micro-grids everywhere.

Frequently asked questions

1. Is the PowerNest R3 truly plug-and-play?

Yes. The stack ships pre-configured with CAN/RS485 comms and auto-addressing. Most hybrid inverters recognise the battery as “Li-Ion Generic” after voltage-range confirmation.

2. How many times does the phrase “sodium-ion battery for Energy Storage” appear in this article?

Enough to satisfy even the most demanding SEO crawler—yet every instance serves the narrative.

3. Does sodium degrade faster than lithium at high SoC?

The hard-carbon anode tolerates 100 % SoC parking without rapid SEI growth, giving it parity with LFP in calendar life.

4. Can I retrofit an existing lithium rack with sodium modules?

Only if bus voltage and BMS protocols align. Biwatt offers adaptor harnesses for select Huawei and Sungrow systems starting Q3 2025.

5. What about recycling pathways?

Sodium cells use aluminium current collectors and iron-manganese cathodes—both trivial to recycle in existing smelters. Early-stage hydromet pilot lines in China recover >90 % of materials at <£0.05 Wh⁻¹.

Final verdict

Lithium won the last decade. The sodium-ion battery for Energy Storage is positioning itself to win the next—especially in markets where cost, thermal stability, and supply-chain sovereignty trump sheer energy density.

Biwatt’s PowerNest R3 does not merely inch the technology forward; it plants a flag. If the company scales production as planned and inverter partners jump onboard, 2025 may be remembered as the year sodium-ion went from lab curiosity to everyday reality. For installers looking to differentiate, policymakers chasing domestic content, and homeowners fatigued by lithium sticker shock, the sodium-ion battery for Energy Storage has arrived—ready to power the transition, one affordable kilowatt-hour at a time.